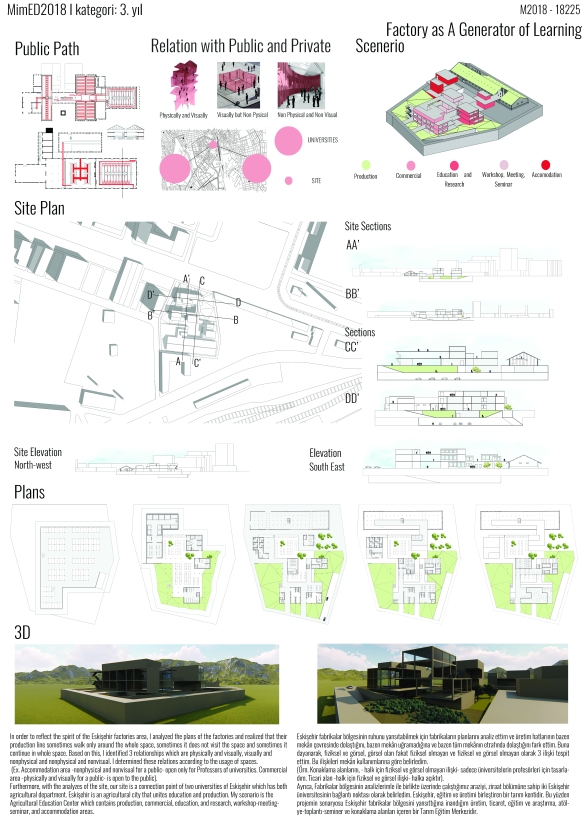

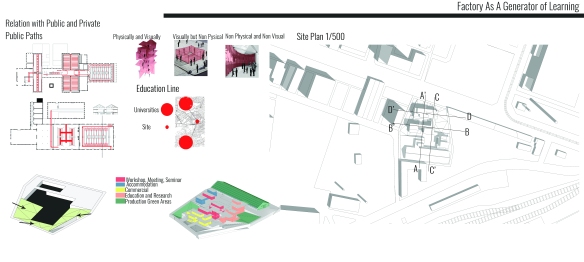

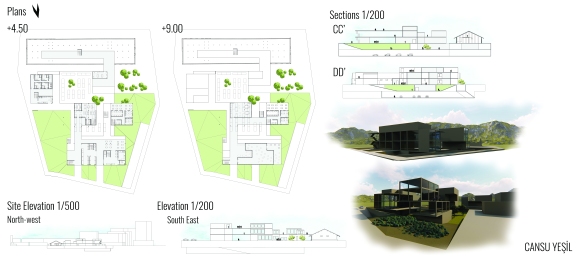

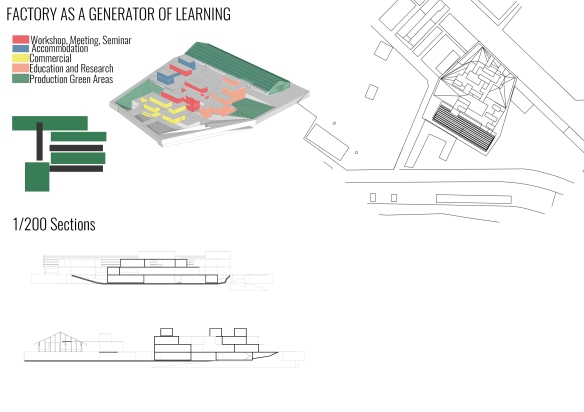

Mimed is a student project competition. I applied to Mimed 2018 third year category with my Factory as A Generator of Learning Project. I passed the pre-election but I could not win a prize.

Category Archives: Arch302

Final Jury

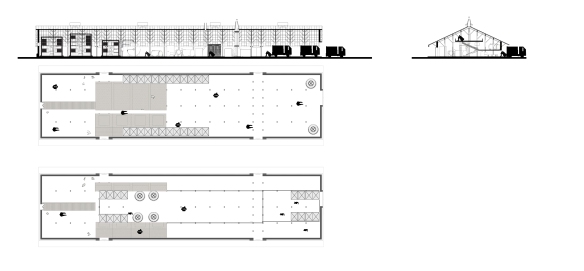

Here is the my design, program was Agricultural Education and Research Center. It contains my analyzes, drawings and 3D modelling.

AGE OF CHANGING “From Standardization To Customization

Standardization is a process of management and promoting that determine consistent features for specific property and service and develop process and technologies which are standard-based and compatible on a particular kinds of industry. Standardization is the method and technique of serial production. Standardization procedures are important in all the organizations as it may guide to better material flow, quality and productivity and serial production which is one of the main sort of organization of mass production, is a technique used in the manufacture of products in consecutive generating made in the same way. As in mass production, products, during the manufacturing process, are in stable motion between each production positions.

The main difference between mass production and serial production is the continuity of the work. In the case of mass production manufacturing of products is carried out on a continuous basis, there is no production breaks. However, serial production, is characterized by the production of a batch of products after which, production is stopped. With serial production, it is possible to adapt the manufacturing machines for the production of a new type of product. Also stopping of production in expectation of another order is commonly used. It is a form of the organization of production which is characterized by a limited kind of unvarying products manufactured in great quantities. The highest form of production specialization is representation of serial production that is allowing the enterprise to concentrate on the output of one or several articles or components of standard dimensions. In the main, with serial production, manufacture can be significantly increased while maintaining or improving property. Because of the special equipment and production tooling are used and the time needed for the preparatory and final operations are minimized, labor productivity increases. Furthermore the cost price is lowered, and profitability is increased. Products of serial production exist as a characteristic of many sectors of industry which are machine building, instruments, light industry, car industry, food industry etc.

However, at the present time, standardization of uniform and process of serial production era has been replaced by mass customization era. These terms represent changing conditions, technology, differentiation of new manufactural methods and forms of application. This is one way to think about the difference between the terms. As meaning, “Serial Production” is large amounts of standardized product are made using production lines, automated robotic machines and human labor. In spite of that “Mass Customization” is defined as the design, engineering and production of large amounts of product on production lines using robotic machines and human labor. Serial production has passed its peak because the expiry of the mass production model continues. At the same time, the way human work, play, learn and consume have also changed gradually. The one size fits all model that worked so beautifully for so many decades has had its day but now people are requiring new products and services that are tailored to their needs, with greater variety and greater frequency. Technology always provides these needs for change that is mass production can’t keep up with. None the less custom is expensive in other words customizing has been expensive, because of risk from design, engineering and prototypes, to manufacturing, including breakage, waste, and the sourcing of materials. The chain of serial production did not come to our daily life in a day. It took time to develop and make progress. Efficient creative thinking was required to design products that could be mass produced, and convince consumers that these goods and services were creditable. In the same way, the age of mass customization needs time to develop. It isn’t yet a household term. It will be, though, once society recognizes it as the way to do things. Furthermore people will realize it’s the fit the solution everyone has all been waiting for. Among other things, companies which are investing in the technologies and processes of mass customization are challenging perceptions, disquieting people with new things that make what people have settled for in the serial production era less and less appealing.

Presently the mass customization capacity is the ability to reliably deliver a high volume of different product alternatives for a relatively large market requiring customization without significant points of sales in terms of cost, delivery and quality. Therewithal, mass customization capability has become a necessity for many producers to survive in a growing competitive environment characterized by heterogeneous customer demands, accelerated new product development investments, and shortened product life cycles. Due to market uncertainty and cash strains, many companies use the order-by-order method. This business model works well when the product range is not very high and there is a lot of demand. However, when the market is not so good, this small volume and high diversity of demands cause the problems of uncertainty in production and the loss of economies of scale. Companies will endure too much of the cost increase caused by less use of capacity and urgent orders. Thus, to succeed in managing high-volume and low-volume production, the company must find ways to increase volume and improve production processes to fully exploit existing production capacity. Coordinated with other facilities in the same company, the facility gives the business the opportunity to bring together some business activities (e.g. purchasing and distribution). On this basis, the facility is flexible to cope with low volume and a wide range of requirements with low cost. On the other hand, the suppliers of supply chain of information and planning of production ensures that the information chain is within the value chain. For this reason, the production varieties that are caused by “Bullwhip” effects and market uncertainties can be reduced by cooperation between all supply chains. The Bullwhip Effect describes a phenomenon in which manufacturers create a large product inventory based on customer demand forecasting. From the assumed position high on the supply chain, a manufacturer can misinterpret consumer purchasing behavior at retail level resulting in a mass of unsaleable stock. As an example for mass customization is 3D printings which use both technology and individualization. As with all things manufacturing, production costs, direct and indirect, remain the primary focus in making decisions. 3D printing generates cost-savings in everything from capital purchase, to eliminating tooling costs and productivity. Beyond that, however, it gives manufacturers an extra edge over the competition.

In a new product promotion scenario, a large number of design iterations and prototypes are taken by products before they are ready for market frequently. By utilizing additive manufacturing, the design cycle is ratably compressed and, in many cases. It is an important advantage over traditional production methods. Not to mention, a faster time to market is a major advantage that can help stabilize short-term costs to ensure mass customization. Another area where the cost of inventory and distribution is reduced, while also helping to justify the high costs of 3D prints, mass customization infrastructures and processes. Mass customization requires a variety of parts where the ability to print on demand parts can help manufacturers significantly save on inventory, storage costs, and transportation cost when distributed.

Finally, mass customization provides a platform for collecting valuable consumer data. When 3D printing allows companies to undertake mass customization, people have access to a vault of new information that they may not have been able to understand before. This information can help you track trends and consumer preferences in real-time. The main issue is that can 3D printing products remove to people the idea of standardization with serial production. Mass customization, i.e. making products to exact customer specifications, low-labor demands and product consolidation, gives 3D printing the potential to break-free of the Bullwhip Effect, therefore leading to the question is that if the bullwhip effect is a critical problem in any supply chain, would 3D production be the solution?

As a consequence, observing a standardized marketing approach in all foreign markets might be attractive to given the cost advantages it carries through the various economies of scale, and the consistent global image it grants the product. However, the differences in the markets indicate that a completely standardized marketing approach may not be appropriate. Setting the marketing strategy to account for these variations increases the product’s chances of success. Thus the nature of a product to be marketed internationally has significant implications for the particular variables that a manager must consider in deciding on the extent of standardization. Setting the marketing strategy to account for these variations increases the product’s chances of success. These factors can also be considered in the segmentation of a company’s global market. The resulting segments will reflect a high degree of intrinsic homogeneity and lead to the use of a high standard marketing approach in a single segment of the market.

Drawing

Dancing of Light Men

This capture taken at İZMİR, TURKEY.

MODELS

Pre-Jury 3

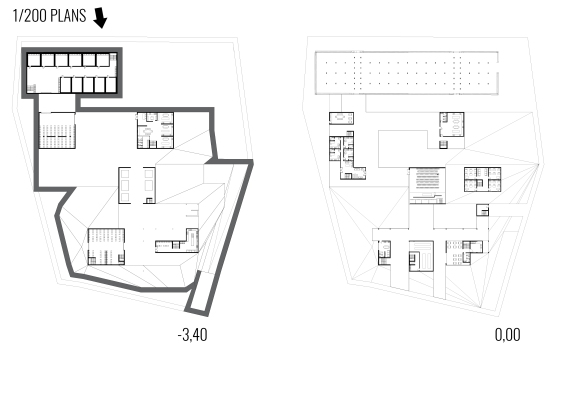

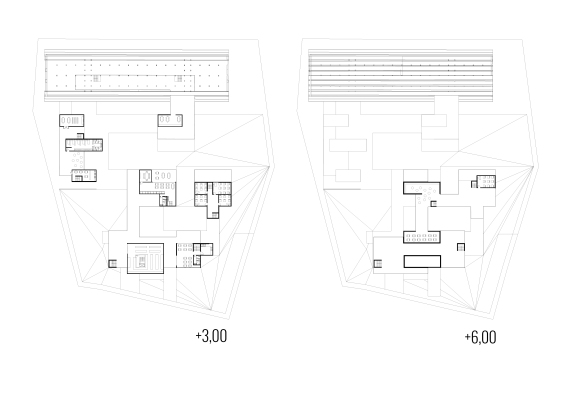

My program was a agricultural education center. Agricultural production continue at registered building, ground and also circulation paths. Furthermore I designed the location of masses according to usage of masses and also their functions.

Prejury 2

After first jury, I decided to change my mass design and also program because my program limited me also it created new problems about design. Because of the education line which it contains Osmangazi University and Anadolu University of Eskişehir had agricultural faculty, I changed to my program as a Agricultural Education Center. This center work as a complex which contains green house, laboratories, education spaces, dormitory, market, restaurant, guesthouse, roof gardens, seminar and meeting space, festival and bazaar areas.

Prejury 1

Firstly I started with what if questions and I applied these questions on my project. I worked on a science center which contains ;

storage, lab refrigerators (chemical storage freezer), do it yourself areas(experimentation), anechoic rooms, laboratories, public areas

My strategy was to Re-introduce factory as an urban space spatialization of the production cycle which is caused by the togetherness of functions in different directions.

Production cycle has both vertical and horizontal movement.

Warehouse Building

We studied on “What if the listed warehouse building in the site is transformed into …”. Firstly I tried to introduce a genuine program for the warehouse building.

“What if the listed warehouse building in the site is transformed into the storage of a science laboratory?”.